Decoding the Enigmatic World of Ceramic Artistry through an Engaging Narrative for Non-Chinese Speakers

The Allure of Ceramics: A Brief Introduction to the Fascinating Craft

Ceramic art has captivated human imagination for centuries, with its intricate designs and delicate craftsmanship evoking a sense of elegance and sophistication. In this article, we will delve into the world of ceramics, exploring the process by which these beautiful pieces are created.

Understanding Ceramic Materials: From Clay to Glaze

At its core, ceramic production revolves around two primary materials: clay and glaze. Clay is a naturally occurring earth material that can be molded into various shapes and forms. Glaze, on the other hand, is a mixture of chemicals applied over the clay surface before firing in a kiln.

Preparing the Canvas: Shaping and Drying

Before any design or pattern can be applied to the ceramic piece, it must first undergo several stages in preparation – from mixing raw materials to shaping them into desired forms.

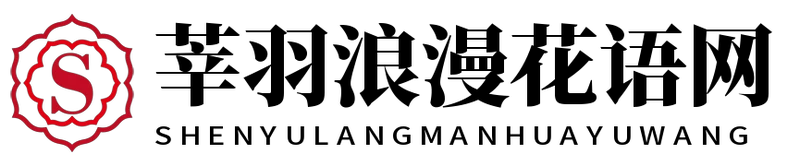

Applying Designs and Patterns: The Artistic Touch

Once shaped, artisans carefully apply their chosen designs onto each piece using techniques such as hand-painting or stamping patterns onto wet clay surfaces.

Firing Up Creativity: The Kiln Process Explained

After applying designs or patterns onto wet clay surfaces, potters place their creations inside high-temperature kilns where they undergo multiple firings at different temperatures.

Bringing Life to Ceramics Through Colorful Glazes

Following firing processes at specific temperatures designed for different types of clays (earthenware vs stoneware vs porcelain), potters meticulously apply glazes that transform plain ceramics into vibrant works-of-art after being fired once again at extremely high temperatures within specially designed kilns called "glazing" kilns.

Enhancing Durability & Aesthetics With Additional Techniques

Some potters may choose to add additional layers like slip-trailing or underglaze painting before re-entering their work in another round within a glazing kiln; others might opt for carving decorative elements directly onto unfired pottery following application of one final layer (usually clear) while still warm out-of-the-kiln - both methods allow further refinement in aesthetics while maintaining durability levels suitable for practical use.

8.Finishing Touches & Quality Control Measures Ensuring Perfection

Upon completion of all necessary steps involved during production cycle including multiple firings followed by careful inspection post-final firing stage involving visual examination under bright light conditions against background colors contrasting with those used throughout entire creative process — thus ensuring optimal color intensity along with minimal flaws—potters finally seal off any open edges using wax prior sealing product packaging containing finished pieces ready-for-retail sale; also adhering relevant health safety guidelines applicable industry standards regarding handling hazardous materials employed throughout manufacturing process itself ensure utmost care taken towards employees working environment protection safety practices adopted across factories producing such masterpieces worldwide today!